Rebuilding an FA24 short block has been a lesson in humility. My first mistake was purchasing an FA24 with a spun rod bearing in the first place. Modern engines aren’t designed to be rebuilt, they’re designed to be purchased.

Case in point; you can’t buy connecting rod bearings for an FA24. Subaru will only sell you rod bearings alongside connecting rods because their connecting rods aren’t reusable. Spinning a rod bearing also means assured destruction of your crankshaft. Add up the cost of a new crankshaft, connecting rods, piston rings, main bearings, and seals, and you’ll find yourself spending within $1500 of a new short block from Subaru.

This could make some semblance of sense if assembling an FA24 was easy. It’s not. Rebuilding an FA24 is closer to rebuilding a Porsche 911 than any car on this side of $40,000 has any right to be.

There are the usual suspects. Everything is sealed with RTV and it needs to be applied just right. Too little and it will leak. Too much and RTV will clog bearings, oil passageways, and/or your oil pan pickup. Being a boxer engine inherently complicates things, as the two halves of the block need to be prepared and glued together. I was prepared for all of that. I’ve done it before on an FA20 and it was fine.

This video may have not been intended for public consumption.

I wasn’t prepared for the FA24’s symmetrical connecting rods. The FA20 has asymmetrical connecting rods angled towards the engine's bottom. Meaning, you can assemble the block with the crank sandwiched inside, install the pistons onto each connecting rod, install the piston/connecting rod assembly in each cylinder, and bolt the connecting rods to the crankshaft. Like any other engine.

Because the FA24’s connecting rods are symmetrical, it’s impossible to bolt them to the crankshaft while the crankshaft is installed in the block. As a result, the connecting rods need to be bolted to the crankshaft first.

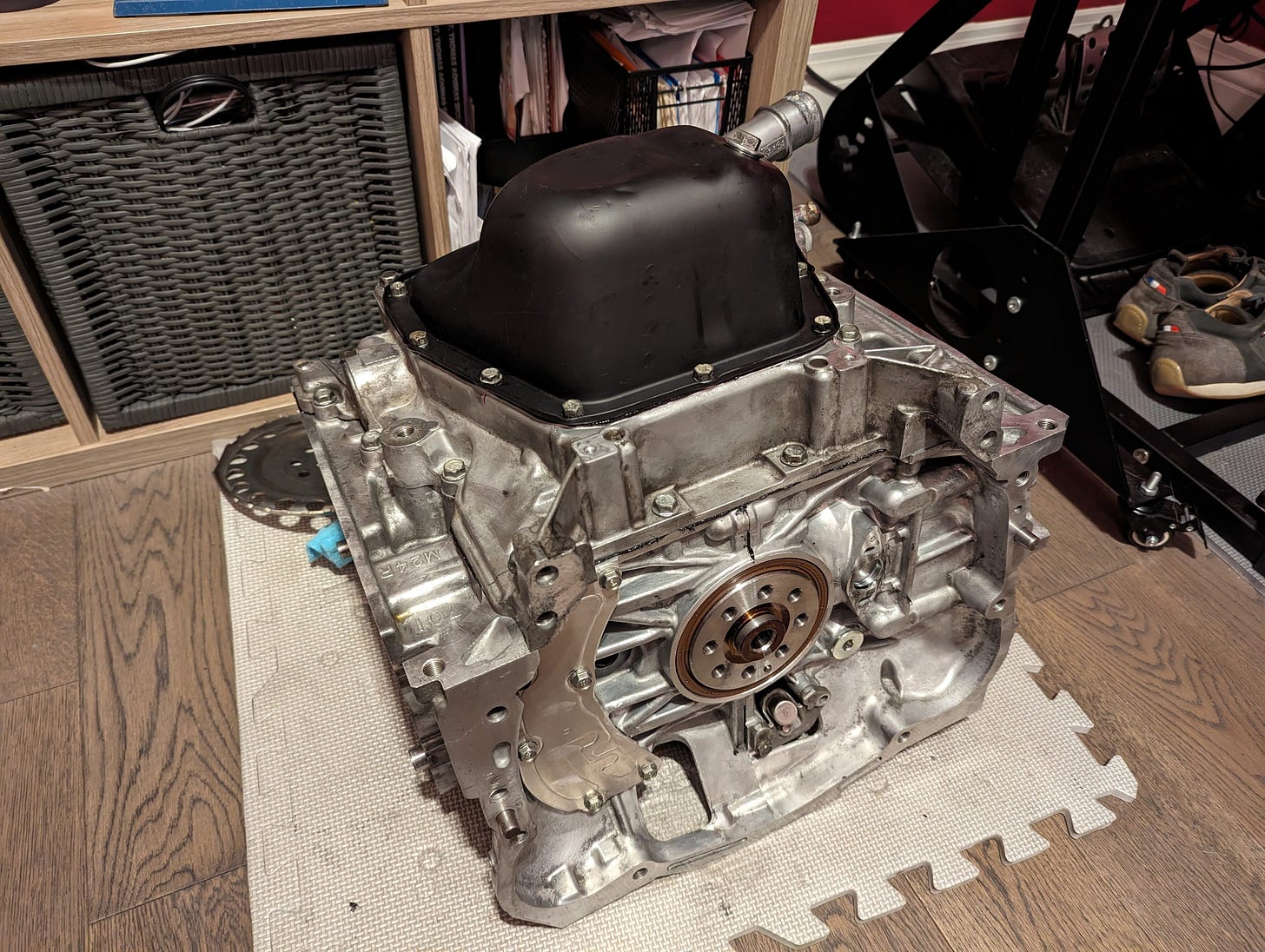

Then the whole crank/con-rod assembly is placed inside the case halves and bolted together using RTV. Then the fun begins. There are holes in the front and back of the block - just large enough to accept a wrist pin. Insert the piston into a cylinder, line it up with the connecting rod using one of those holes, and insert the wrist pin. This required strategic wiggling of the crankshaft, the lightest tap of a hammer, a mountain of assembly lube, and immense patience.

Do that, seal the holes with supplied plugs, and you have a Subaru short block.

If you’ve made it this far, you’re probably asking the same question I was: why. Why do any of this? Why build an FA24? Why attempt to install it in a Gen 1 BRZ? Why install it in the worst BRZ imaginable, and doom myself to a month of body work? None of this makes sense. All of this is deeply irrational. Yes, I know that Subaru will sell me a new 2024 Subaru BRZ.

Car people fall into two camps; those who understand this, and those who don’t. And that distinction comes down to where you find joy: in the process, or in the net result. Would you prefer to build Lego sets or peruse art museums; turn wrenches or row gears? These two extremes exist on a spectrum. Most of us fall somewhere in the middle, but I have friends who’d rather run a racing team than drive the racecar, and others that, well, buy cars for their potential as a driver’s car and can’t finish them because the process is grueling.

Both of these experiences feel cursed. Those that wrench, especially when it comes to projects like mine, appear to be masochists. At its best, it’s an enormously time-consuming slog: I’ve been working on the BRZ for five months all I have to show is a rolling chassis and a short block on my office floor. That’s not for lack of trying. These things take time, something that’s easy to forget in a world of last-minute SEMA builds and Youtube project cars. Things get more complicated when you don’t have a team of people, and your car actually needs to work on a racetrack.

But I don’t envy the other side of the fence. Think about every person you know who hops into a new car every two years. The ones who live on Autotrader, are constantly sharing listings despite insisting they love their car. Odds are that you, reader, are one of them. Personally, it sounds exhausting. Constant longing. At least the frustration that comes with wrenching is periodically interrupted by intense satisfaction: the kind you enjoy when you turn over your freshly assembled FA24 for the first time.

I spend an unhealthy amount of time thinking about the traps that people fall in, a consequence of making a living in the gaming industry. I think there’s a lot of value in knowing who you are. Because this community spends an enormous amount of time and money convincing you that you need to make your mark, that building a car is a mark of pride. Buying something off a dealer lot is weakness. Lest we forget that a half-a-trillion-dollar auto parts industry relies on you to believing that.

Furthermore, and I mean this, that constant cycle of buying and selling, chasing new experiences, comes with massive benefits; you drive a lot of different cars, and you gain a whole lot of free time (emphasis on the latter). Because behind so many projects are miserable partners. These things can take over your life if you aren’t careful.

As for me, somehow I’m trying to do both. I have an insatiable need to tinker, build, and optimize, but I love driving. The BRZ will, for the foreseeable future, be that project. I know the platform well, I love how it drives, and I have enough parts to get me through another decade of racetrack shenanigans. But I’ll always have an all-weather driver’s car. Right now that’s a ‘21 VW GTI on my driveway: versatile, quick, and just interesting enough without being a nuisance. I’ll probably pickup S550 Mustang GT in the near term. As the saying goes, life’s too short to drive boring cars.

Yes - the FA24 swap guide is coming up. Just putting the finishing touches on what’s proven to be a massive endeavor. Stay tuned for that.

What plugs did you use to seal the service holes for the front of the block?